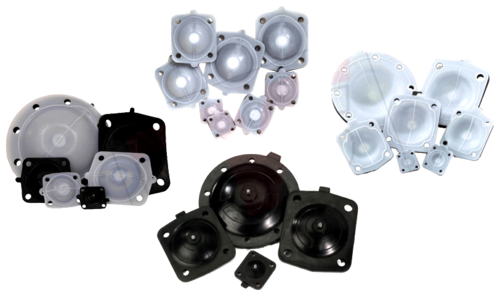

PTFE Diaphragm

Product Details:

- Type PTFE / EPDM Laminate Diaphragm

- Material Virgin PTFE bonded to EPDM elastomer

- Working Temperature -40C to +160C Celsius (oC)

- Density 2.2 Gram per cubic centimeter(g/cm3)

- Tensile Strength 6 18 MPa (depending on layer) Megapascals (MPa )

- Thickness 1 mm 10 mm (typical range) Millimeter (mm)

- Melting Point PTFE up to 327C; EPDM does not melt but decomposes above 180C

- Click to View more

PTFE Diaphragm Price And Quantity

- 1 Piece

- 50 INR/Piece

PTFE Diaphragm Product Specifications

- 1 mm 10 mm (typical range) Millimeter (mm)

- Virgin PTFE bonded to EPDM elastomer

- Customizable (standard: up to 1.5 m) Nanometer (nm)

- PTFE / EPDM Laminate Diaphragm

- 2.2 Gram per cubic centimeter(g/cm3)

- 6 18 MPa (depending on layer) Megapascals (MPa )

- -40C to +160C Celsius (oC)

- Custom sizes available

- Customizable/roll form Millimeter (mm)

- PTFE up to 327C; EPDM does not melt but decomposes above 180C

PTFE Diaphragm Trade Information

- 100 Piece Per Week

- 1 Week

- All India

Product Description

J. KHUSHALDAS & CO. (SPD) provides a compressive of diaphragms with different designs. This PTFE diaphragms with TFM film bonded is widely used for applications with chemically aggressive media and high temperatures. The TFM layer improves the mechanical properties and lower permeability compared to traditional PTFE. Its quality complies with FDA, USP and ISO standards.

PTFE / EPDM Diaphragm is a highly durable and economical industrial-grade seal that can be used in liquid and air-powered machines to prevent leakages.It is manufactured by using advanced production technologies that make it free from manufacturing flaws and give high dimensional accuracy. Premium-class thermoplastic materials are used for the fabrication of thesePTFE / EPDM Diaphragm that results in high strength to weight ratio and excellent resistance against abrasion, rust, and high temperatures.

Exceptional Chemical and Corrosion Resistance

PTFE / EPDM Laminate Diaphragms resist a wide range of aggressive chemicals, including acids, alkalis, and solvents. The virgin PTFE surface provides outstanding protection in harsh environments, making these diaphragms ideal for chemical processing and industrial applications where corrosion resistance is critical.

Customizable for Optimal Performance

Available in round, rectangular, or customized shapes, these diaphragms can be produced in various sizes, widths (up to 1.5 m), thicknesses (110 mm), and roll forms. The fabric-reinforced core and selectable durometer hardness (6075 Shore A) of the EPDM layer ensure tailored solutions to meet unique operational requirements.

Designed for Long-Term Reliability

Featuring excellent aging resistance and very low compression set, PTFE / EPDM Diaphragms maintain superior leak-tightness and mechanical integrity even during long-term operation. Their robust construction allows continuous, reliable sealing under varying pressures and temperatures from -40C to +160C.

FAQs of PTFE / EPDM Diaphragm:

Q: How can PTFE / EPDM Diaphragms be customized to suit specific applications?

A: PTFE / EPDM Diaphragms can be fabricated in round, rectangular, or custom shapes with various sizes, thicknesses (110 mm), and widths up to 1.5 meters. Customization extends to durometer hardness and surface finish, ensuring seamless integration with diverse pumps, valves, and process equipment.Q: What are the benefits of using a PTFE / EPDM Laminate Diaphragm in chemical process equipment?

A: These diaphragms offer outstanding chemical and corrosion resistance, ensuring reliable operation with acids, alkalis, and solvents. Their excellent leak-tightness, negligible permeability, and high aging resistance make them an ideal choice for maintaining safety and performance in aggressive environments.Q: Where are PTFE / EPDM Diaphragms commonly used?

A: They are widely applied in pumps, valves, and chemical process equipment across industries such as chemical manufacturing, water treatment, and pharmaceuticals, especially where high resistance to chemicals and long-term sealing performance are essential.Q: How does the dual material construction enhance diaphragm performance?

A: The virgin PTFE face delivers exceptional chemical resistance and a smooth sealing surface, while the EPDM side provides flexibility, excellent compression set, and a textured grip for enhanced mechanical bonding, thanks to a fabric-reinforced core that ensures durability under fluctuating pressure.Q: When is it advantageous to select a PTFE / EPDM diaphragm over conventional elastomer diaphragms?

A: PTFE / EPDM diaphragms are preferable when exposure to aggressive chemicals, temperature extremes, or the need for minimal permeability is anticipated. Their laminate structure protects against corrosion and ensures long-lived leak-tight operation, reducing maintenance frequency.Q: What is the typical process for acquiring a custom-sized PTFE / EPDM diaphragm from Indian manufacturers or suppliers?

A: Customers can collaborate with distributors, exporters, manufacturers, suppliers, or traders in India by specifying dimensions, shape, thickness, and desired reinforcements. Orders may be placed for standard sizes or custom requirements to match specific equipment and installation needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

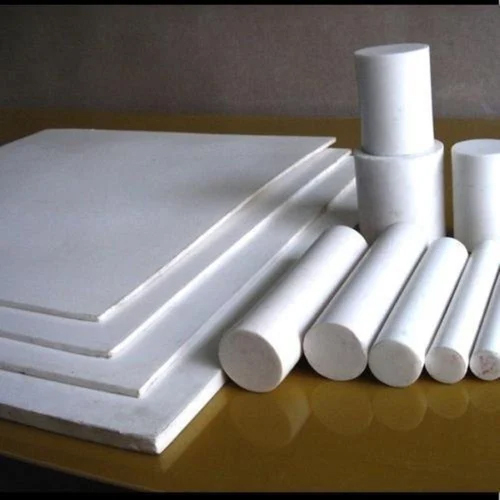

Other Products in 'PTFE Products' category

|

J. KHUSHALDAS & CO. (SPD)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS Call Me Free

Call Me Free

Send SMS

Send SMS Call Me Free

Call Me Free