Asbestos Jointing Sheets

Product Details:

Asbestos Jointing Sheets Price And Quantity

- 100

Asbestos Jointing Sheets Trade Information

- 100 Per Week

- 1 Week

Product Description

Asbestos Jointing Sheets

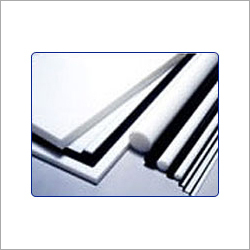

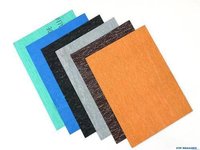

Well backed by a wide distribution network and reliable vendor base, we are trading and supplying a premium range of Asbestos Jointing Sheets. Manufactured using premium grade chryssotile asbestos fibre and heat resisting rubber, these sheets are used in marine engines and electricity generating sets. Our Asbestos Jointing Sheets are appreciated for their attributes like pressure & temperature resistance, light weight and durable finish. Furthermore, we can also customize these sheets as per the needs of the clients.

Further Details:

- Saturated stream

- Oxygen

- Petroleum distillates

- Oils & fats

- Fuels

- Internal combustion engines

- Hydrocarbons

- Solvents

- Dyes

Compressed Asbesto Fibre Jointing is a consistently uniform and resilient product. A price worthy quality of dependable performance, plus adaptability to many sealing requirements marks this 'Steam Jointing the choice sheet packing of plant Engineers and maintenance men.

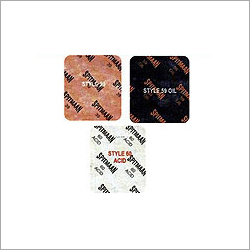

Spitmaan style 20 jointings are developed for general purpose applications and this quality is applicable to a wide range of duties with less severe working conditions of temperature and pressure.

This is a specialized Asbestos Fibre Jointing sheet which is intimately bonded with Acid resisting compound, to with stand the corrosive action of acids and chemicals. Recommended for use against hot concentrated organic, inorganic and mineral acids including hydrochloric, sulphuric(oleum) and nitric acids, under service conditions of temperature and pressures commonly encountered in chemicals industries

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Asbestos and Non Asbestos Products' category

|

J. KHUSHALDAS & CO. (SPD)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS

Send SMS

Send SMS