Non Metallic Gaskets

10-5000 INR/Kilograms

Product Details:

- Standard ASME, DIN, BS, IS, ANSI

- Working Temperature -200C to +500C

- Medium Oils, water, steam, chemicals, gases

- Temperature Resistance upto 500C

- Gasket Coefficient m=2.5 to 4.0

- Vaccum Range up to 1x10 torr

- Pressure Resistance upto 100 bar

- Click to View more

X

Non Metallic Gaskets Price And Quantity

- 10-5000 INR/Kilograms

Non Metallic Gaskets Product Specifications

- up to 1x10 torr

- upto 500C

- m=2.5 to 4.0

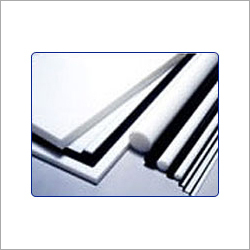

- Non-metallic (compressed fibre, rubber, PTFE, graphite, CNAF, etc.)

- upto 100 bar

- 50 to 80 Shore A

- 0.5 mm to 5 mm

- -200C to +500C

- Flange sealing, piping systems, heat exchangers, pumps, valves

- Round, Oval, Custom shapes

- ASME, DIN, BS, IS, ANSI

- Customized as per requirement

- Oils, water, steam, chemicals, gases

Non Metallic Gaskets Trade Information

- 100 Per Week

- 1 Week

- All India

Product Description

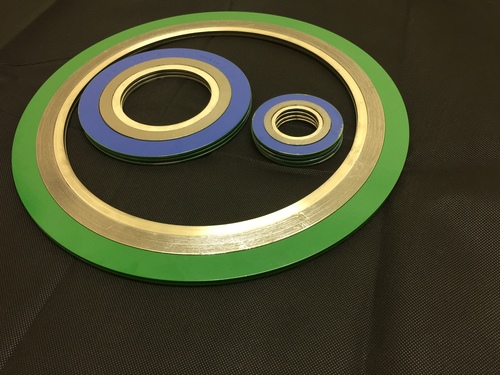

Experience stellar sealing performance with our Non-Metallic Gasketsan unbeatable price for a must-have solution in critical industrial applications. Highly recommended for industries requiring classic reliability, these gaskets feature a smooth or anti-stick surface, exceptional chemical resistance, and robust tensile strength. Available in a range of densities (1.6 to 2.0 g/cm), colors, and thicknesses, they are suitable for customized flange sealing, piping, heat exchangers, and more. Choose from a variety of shapes, materials, and packaging options for optimal convenience and performance. Certified to international standards and built to last, these gaskets stand as a pivotal addition to any sealing solution portfolio.

Unmatched Versatility and Advantages

Non-Metallic Gaskets are widely used across diverse sectors, including chemical processing, power generation, and water treatment. Their primary competitive advantages are excellent adaptability to corrosive environments, customizable sizing, and superior fit for complex shapes. Used as pivotal sealing elements, these gaskets prevent leaks in flanges, valves, heat exchangers, and pumps, ensuring reliable operational integrity even under extreme conditions. Their extended durability and flexibility make them a classic choice for demanding industrial environments.

Market Reach, Premium Certifications, and Reliable Supply

Our Non-Metallic Gaskets enjoy strong market value across India and international markets. Supported by premium certifications such as ASME, DIN, BS, IS, and ANSI, they assure consistent quality and performance. We maintain a robust supply chain and logistics network to accommodate domestic market needs and bulk orders with ease. Our supply ability ensures timely delivery and customer satisfaction, cementing our status as a trusted supplier, distributor, and exporter in the gasket industry.

Unmatched Versatility and Advantages

Non-Metallic Gaskets are widely used across diverse sectors, including chemical processing, power generation, and water treatment. Their primary competitive advantages are excellent adaptability to corrosive environments, customizable sizing, and superior fit for complex shapes. Used as pivotal sealing elements, these gaskets prevent leaks in flanges, valves, heat exchangers, and pumps, ensuring reliable operational integrity even under extreme conditions. Their extended durability and flexibility make them a classic choice for demanding industrial environments.

Market Reach, Premium Certifications, and Reliable Supply

Our Non-Metallic Gaskets enjoy strong market value across India and international markets. Supported by premium certifications such as ASME, DIN, BS, IS, and ANSI, they assure consistent quality and performance. We maintain a robust supply chain and logistics network to accommodate domestic market needs and bulk orders with ease. Our supply ability ensures timely delivery and customer satisfaction, cementing our status as a trusted supplier, distributor, and exporter in the gasket industry.

FAQs of Non Metallic Gaskets:

Q: How are the Non-Metallic Gaskets installed in different systems?

A: Non-Metallic Gaskets can be installed manually or through automated processes, making them suitable for a variety of industrial systems such as flanges, piping, pumps, and valves.Q: What materials are used in the manufacturing of these gaskets?

A: These gaskets are crafted from high-quality non-metallic materials including compressed fibre, rubber, PTFE, graphite, and CNAF, selected based on desired chemical and temperature resistance.Q: What benefits do Non-Metallic Gaskets offer over metallic alternatives?

A: They provide excellent chemical resistance, flexible installation options, and customized shapes, making them ideal for applications requiring adaptability and resistance to acids, alkalis, solvents, and extreme temperatures.Q: Where can Non-Metallic Gaskets be used?

A: They are extensively used in industrial settings such as chemical processing plants, power plants, water treatment facilities, and any process requiring effective leak prevention in fluid or gas systems.Q: What is the lifespan and maintenance requirement of these gaskets?

A: The lifespan depends on the application and medium, typically ranging from 1 to 5 years. With proper usage and regular inspections, they deliver long-lasting service with minimal maintenance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Gaskets' category

|

J. KHUSHALDAS & CO. (SPD)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS

Send SMS

Send SMS