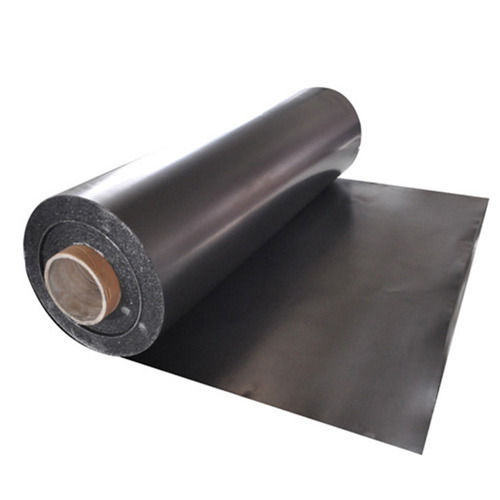

Flexible Graphite Sheet

10-5000 INR/Kilograms

Product Details:

- Material Flexible Graphite

- Application Industrial Sealing, Gaskets, Heat Insulation

- Chemical Composition Pure Graphite (Carbon content > 99%)

- Shape Sheet

- Hardness 35~45 Shore A

- Density 1.0 Gram per cubic centimeter(g/cm3)

- Click to View more

X

Flexible Graphite Sheet Price And Quantity

- 10-5000 INR/Kilograms

Flexible Graphite Sheet Product Specifications

- 35~45 Shore A

- 1.0 Gram per cubic centimeter(g/cm3)

- Industrial Sealing, Gaskets, Heat Insulation

- Flexible Graphite

- Sheet

- Pure Graphite (Carbon content > 99%)

Flexible Graphite Sheet Trade Information

- 100 Per Week

- 1 Week

Product Description

With the help of our distinguished professionals, our company has been able to mark its strong presence in the market as one of the well known manufacturers and exporters of Flexible Graphite Products. The graphite products, offered by us are engineered using topmost quality materials in compliance with international standards. In addition to this, our quality controllers check the products on certain parameters and set industry norms. Offered Graphite Sheet are acknowledged due to their longer service life, effective performance and corrosion resistance features.

Technical Specifications:

| Type: | Expanded Sheet |

| Grade: | Industrial Grade |

| Hardness: | 80 shore C |

| Conductivity y vertical direction: | 5~20W/m.k |

| Tensile strength: | 715PS |

| Application: | Seal |

| C Content (%): | above 99% or according to customers' requests |

| Flame rating: | V-0 |

| Conductivity x vertical direction: | 300~1500W/m.k |

| Thickness: | 0.15mm to 8mm (+-0.03) |

| Material: | Natural Graphite |

| Continuous use temp: | -40~+500 |

Outstanding Industrial Versatility

Flexible Graphite Sheets are engineered for demanding industrial applications, including sealing, heat insulation, and gasket fabrication. Their robust construction and adaptability make them suitable for various industries that require chemical and thermal resistance. Their customizable dimensions provide versatility for numerous projects and requirements.

Reliable Performance and Durability

Manufactured from high-purity graphite, these sheets exhibit a high tensile strength (>4.5 MPa) and a density of 1.0 g/cm, ensuring mechanical stability and long-term durability. Enhanced with a smooth finish and optimal hardness (35~45 Shore A), they offer exceptional performance even under harsh conditions and extensive usage cycles.

FAQs of Flexible Graphite Sheet:

Q: How is flexible graphite sheet used in industrial sealing and gaskets?

A: Flexible graphite sheet serves as an excellent material for industrial sealing and gaskets due to its high compression ratio, chemical inertness, and ability to form tight, leak-proof seals. It is cut or shaped to fit various flanges and joints, maintaining performance even at high temperatures and pressures.Q: What is the standard process for cutting and installing flexible graphite sheets?

A: Flexible graphite sheets can be cut using simple tools such as knives or shears, making them easy to shape to specific dimensions. During installation, the sheet is placed between mating surfaces and compressed to form a seal, usually without the need for binders or adhesives.Q: When should I choose flexible graphite sheets over other sealing materials?

A: Flexible graphite sheets are preferred when applications demand a wide pH tolerance, high temperatures, excellent thermal conductivity, and resilience to aggressive chemicals. They are especially valuable when a smooth surface, minimal sulfur and chloride content, and superior sealing are required.Q: Where can flexible graphite sheets be most effectively applied?

A: These sheets are widely used in refineries, chemical plants, power generation, and industrial equipment requiring reliable sealing, heat insulation, and resistance to chemicals. Their flexibility makes them suitable for both static and dynamic sealing environments.Q: What are the key benefits of using a pure graphite sheet with low sulfur and chloride content?

A: High purity, with minimal sulfur (<1200 ppm) and chloride (50 ppm) content, ensures negligible corrosion and contaminant risk. This enhances the sheets longevity and maintains the integrity of sensitive industrial systems, especially in chemical and petrochemical sectors.Q: How does the compression ratio of 3545% enhance the performance of flexible graphite sheets?

A: The optimal compression ratio provides a balance between adaptability and sealing strength. It allows the sheet to conform well to surface irregularities while maintaining integrity under pressure, preventing leakage and ensuring reliable long-term operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Graphite Sheet' category

|

J. KHUSHALDAS & CO. (SPD)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS Call Me Free

Call Me Free

Send SMS

Send SMS Call Me Free

Call Me Free