Nylon Sheet

10-5000 INR/Kilograms

Product Details:

- Product Type Nylon Sheet

- Plastic Type Nylon

- Plastic Molding Type Extruding

- Thickness 2 mm to 100 mm

- Density 1.14 Gram per cubic centimeter(g/cm3)

- Strength High Tensile Strength

- Shape Rectangular / Sheet

- Click to View more

X

Nylon Sheet Price And Quantity

- 10-5000 INR/Kilograms

Nylon Sheet Product Specifications

- High Tensile Strength

- 1.14 Gram per cubic centimeter(g/cm3)

- Nylon Sheet

- Rectangular / Sheet

- 2 mm to 100 mm

- Nylon

- Extruding

Nylon Sheet Trade Information

- 100 Per Week

- 1 Week

- All India

Product Description

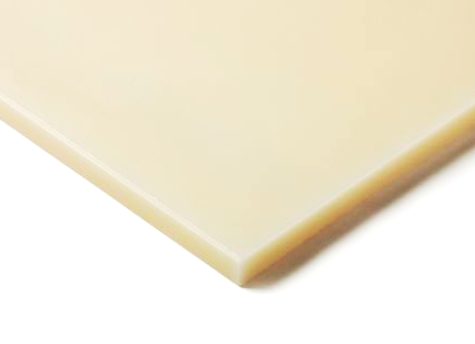

Nylon Sheets are made from the engineering resins. The said sheets are suited for assorted applications. They are demanded in the sectors of electronic, automotive and marine. They are also apt for making the carpet. They are known well for their low coefficient of friction. Nylon Sheets are known well for their outstanding wear resistance as well as low frictional properties.In addition, these have excellent resistance against abrasion & wear. These sheets allow for simple machining.

Superior Mechanical Strength for Industrial Applications

Nylon sheets are recognized for their remarkable tensile strength and excellent impact resistance. These properties make them an outstanding choice for manufacturing gears, bearings, and wear strips used in heavy machinery, reducing maintenance costs and extending equipment life.

Precision and Versatility in Every Sheet

Manufactured using the extruding process, our nylon sheets ensure uniform thickness and a smooth surface finish. This allows for easy machining and customization to meet a wide array of industrial requirements, whether for insulation parts or custom-cut components.

Reliable Performance in Harsh Environments

With a temperature tolerance ranging from -40C to 100C and a low water absorption rate, these nylon sheets remain dimensionally stable and effective even in challenging conditions. Their high melting point (220C) further assures secure operation under thermal stress.

FAQs of Nylon Sheet:

Q: How can nylon sheets be used in industrial applications?

A: Nylon sheets are commonly used in a variety of industrial applications such as gears, bearings, wear strips, and insulation parts due to their high tensile strength, excellent impact resistance, and dimensional stability under thermal and mechanical stress.Q: What are the benefits of choosing extruded nylon sheets over other materials?

A: Extruded nylon sheets provide a unique combination of high tensile strength, smooth surface finish, and superior impact resistance compared to many other plastics. Their low water absorption and ability to withstand a wide temperature range make them ideal for environments requiring durability and precision.Q: When is it advisable to use nylon sheets instead of metal for components?

A: Nylon sheets should be considered over metal when weight reduction, corrosion resistance, quieter operation, or lower maintenance are priorities. They also perform well in applications that benefit from self-lubricating properties and non-conductive materials, such as insulation parts.Q: Where are your nylon sheets manufactured and supplied from?

A: Our nylon sheets are manufactured, exported, and supplied across India. We operate as a distributor, exporter, manufacturer, supplier, and trader, ensuring a steady and reliable supply for both domestic and international clients.Q: What is the process used to make your nylon sheets?

A: These nylon sheets are produced through the extrusion process, which involves shaping the nylon material under high pressure and temperature to achieve a consistent, smooth finish and precise dimensions across the length, width, and thickness needed.Q: How can the size and thickness of nylon sheets be customized for specific needs?

A: We offer nylon sheets in lengths from 1000 mm to 3000 mm, widths from 500 mm to 1250 mm, and thicknesses ranging from 2 mm to 100 mm. Custom sizes can be accommodated to ensure optimal fit and performance for your application.Q: What are the usage advantages of nylon sheets in challenging environments?

A: Nylon sheets perform exceptionally well in challenging environments due to their ability to tolerate temperatures from -40C to 100C, resist wear, and maintain strength. Their low water absorption and high melting point (220C) also contribute to their suitability for both indoor and outdoor industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Engineered Plastics Products' category

|

J. KHUSHALDAS & CO. (SPD)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS Call Me Free

Call Me Free

Send SMS

Send SMS Call Me Free

Call Me Free