UHMWPE Sheet

Product Details:

- Product Type UHMWPE Sheet

- Plastic Type Ultra High Molecular Weight Polyethylene (UHMWPE)

- Plastic Molding Type Extrusion / Compression Molding

- Thickness 10 mm - 100 mm

- Density 0.96 Gram per cubic centimeter(g/cm3)

- Strength High Impact and Wear Resistance

- Shape Rectangular Sheet

- Click to View more

UHMWPE Sheet Price And Quantity

- 10-5000 INR/Kilograms

UHMWPE Sheet Product Specifications

- UHMWPE Sheet

- Rectangular Sheet

- 0.96 Gram per cubic centimeter(g/cm3)

- Ultra High Molecular Weight Polyethylene (UHMWPE)

- High Impact and Wear Resistance

- 10 mm - 100 mm

- Extrusion / Compression Molding

UHMWPE Sheet Trade Information

- 100 Per Week

- 1 Week

- All India

Product Description

UHMWPE Sheets areoften suited for the lining of chutes as well as hoppers. Their task is to protect the metal surfaces and keep the solid materials moving slowly. These are suited for the manufacturing of hydraulicbearings and seals. The provided sheets are apt to perform the medium mechanical duties in water, pneumatics, oil hydraulics, and unlubricated applications. UHMWPE Sheets are accessible with the good abrasion resistance and are suited to be kept on the soft mating surfaces.These sheets also boast ofexcellent waterproof capabilities and high abrasion resistance.

Product details

| Material | Polyethylene |

| Thickness | 6 to 300 mm |

| Width | 1220 to 1150 mm |

| Color | Black & White |

| Brand | JK |

Exceptional Chemical and UV Resistance

UHMWPE sheets exhibit unparalleled resistance to a wide variety of chemicals, solvents, and UV radiation. This outstanding property makes them ideal for environments where standard plastics may degrade. Their minimal water absorption and reliable performance under harsh conditions ensure suitability for food processing, industrial, and outdoor applications.

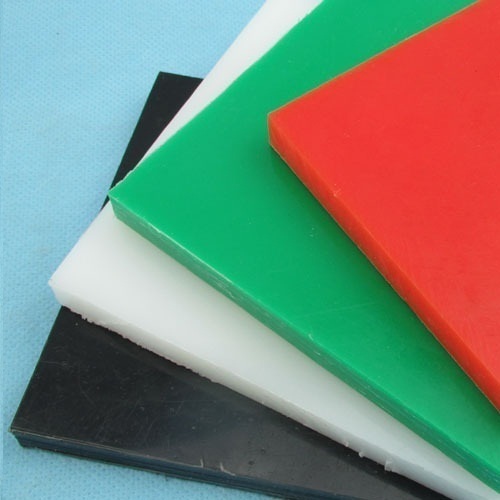

Versatile Shape and Customization Options

Available in rectangular form and smooth finishes, UHMWPE sheets can be supplied in standard white or custom colors to match your specific requirements. Their thickness, length, and width can be tailored, providing flexibility for different uses from custom machine parts to industry-specific solutions.

Reliable Performance in Extreme Conditions

With an operating temperature range of -269C to +80C, UHMWPE sheets perform effectively in both cryogenic and moderately high-temperature applications. Their high impact resistance and robust mechanical properties make them the preferred choice for machine components requiring longevity and dependability.

FAQs of UHMWPE Sheet:

Q: How can UHMWPE sheets be used in industrial settings?

A: UHMWPE sheets are commonly utilized as chute liners, bearings, gears, and machine parts thanks to their low friction and high wear resistance. Their excellent durability and performance in harsh conditions make them reliable for heavy-duty industrial and conveyor system applications.Q: What benefits do UHMWPE sheets offer compared to other plastics?

A: UHMWPE sheets stand out with their exceptional impact strength, low coefficient of friction, and extraordinary chemical resistance. They are less likely to absorb moisture, are non-toxic, UV resistant, and suitable for food contact (FDA approval available), outperforming many traditional plastics in demanding roles.Q: When is it advisable to select a customized UHMWPE sheet?

A: Custom UHMWPE sheets are recommended when specific dimensions, surface finishes, or colors are necessary to meet unique project requirements. Customized options ensure precise fitting and optimal performance for specialized machinery or industry-specific demands.Q: Where are UHMWPE sheets most frequently applied?

A: These sheets are widely used in sectors such as food processing, mining, packaging, and material handling. Their robustness and versatility make them ideal for conveyor systems, chute linings, and as components in gear and bearing assemblies.Q: What is the process for manufacturing UHMWPE sheets?

A: UHMWPE sheets are produced using extrusion or compression molding techniques. These processes ensure a smooth surface finish, uniform material properties, and allow for customized sizing to meet varied industry requirements.Q: Is FDA approval available for UHMWPE sheets intended for food industry use?

A: Yes, FDA approval can be provided upon request, making UHMWPE sheets suitable for use where food contact safety is essential, especially in food processing and conveying systems.Q: How does the operating temperature range affect the usage of UHMWPE sheets?

A: The broad operating temperature range (-269C to +80C) allows UHMWPE sheets to function reliably in extremely cold or moderately hot environments, enhancing their usability in specialized industries such as cryogenics, processing plants, and outdoor applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Engineered Plastics Products' category

|

J. KHUSHALDAS & CO. (SPD)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS Call Me Free

Call Me Free

Send SMS

Send SMS Call Me Free

Call Me Free