Mill Board

10-5000 INR/Kilograms

Product Details:

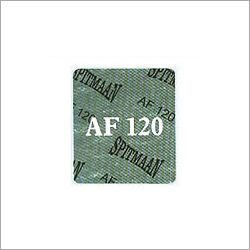

- Product Type Industrial Thermal Insulation Board

- Type Mill Board

- Material

- Shape Rectangular/Square

- Working Temperature Up to 400C

- Working Presssure High Pressure Resistant

- Density 1.6 Gram per cubic centimeter(g/cm3)

- Click to View more

X

Mill Board Price And Quantity

- 10-5000 INR/Kilograms

Mill Board Product Specifications

- Heat Insulation, Fire Resistant

- Rectangular/Square

- Industrial Thermal Insulation Board

- Up to 400C

- 1.6 Gram per cubic centimeter(g/cm3)

- High Pressure Resistant

- Off White, Grey

- Mill Board

- 1mm to 25mm

Mill Board Trade Information

- 100 Per Week

- 1 Week

Product Description

Mill Board offered by us, is a thick, durable paperboard useful for lining book covers and furniture panels. Craft scraping paper and wood pulp are used to make this board. Our product is finished on both sides, has a high strength, and is of the highest quality. Apart from this, Mill Board is used in a variety of industries for applications such as automobile gaskets, padding, roller conveyor construction, fire safety, environmental safety, protection and equipment, and more.

Premium Heat and Fire Resistance

Designed for environments demanding robust thermal and fire protection, our mill boards exhibit a compressive strength of 40 to 50 kg/cm and water absorption below 20%. They are ideal for high-temperature applications including furnace linings and fire doors, offering long-lasting resistance in critical industrial settings.

Versatile Industrial Applications

From electrical panels to furnace insulation and fire door construction, our mill boards are engineered to fulfill various industrial purposes. Their excellent density (1.6 g/cm) ensures superior insulation, while the range of sizes and thicknesses allows adaptation to distinct project needs. Meaningful usage lies in their capacity to maintain structural integrity under challenging conditions.

FAQs of Mill Board:

Q: How is mill board used in furnace insulation and electrical panels?

A: Mill board is primarily utilized as a heat and fire-resistant barrier in furnace insulation and electrical panels. Its low moisture content and high compressive and tensile strength enable it to protect equipment and structures from excessive heat, prevent fire spread, and ensure operational safety in high-pressure environments.Q: What makes this mill board suitable for high-pressure and high-temperature applications?

A: The boards robust construction using asbestos fiber and specialized fillers provides considerable compressive strength (4050 kg/cm) and a working temperature threshold of up to 400C. This, coupled with its density and low water absorption, ensures it maintains performance even under intense conditions.Q: When should I consider choosing mill board for my project?

A: Mill board is recommended when your project demands reliable thermal insulation, fire resistance, and structural durability, such as in furnace linings, fire protection doors, or electrical panel enclosures. Its versatile thickness and sizes accommodate various industrial requirements.Q: Where are your mill boards typically supplied and in what shapes and sizes?

A: We distribute, export, and supply mill boards throughout India and internationally. The boards are available in rectangular and square shapes, with lengths from 1 to 1.2 meters, widths from 500mm to 1000mm, and thickness options between 1mm and 25mm for maximum adaptability.Q: What is the manufacturing process of your mill board?

A: Our mill boards are manufactured using advanced techniques that involve thoroughly blending asbestos fibers and other specialized fillers. The mixture is pressed to the desired thickness, cured, and then surface-finished smoothly for optimal suitability in high-temperature, industrial insulation settings.Q: How does mill board benefit industrial facilities?

A: Mill boards provide crucial benefits such as enhanced fire protection, reduced heat loss, and reliable insulation. These properties improve workplace safety, contribute to equipment longevity, and help facilities meet strict fire and thermal regulations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Asbestos and Non Asbestos Products' category

|

J. KHUSHALDAS & CO. (SPD)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS Call Me Free

Call Me Free

Send SMS

Send SMS Call Me Free

Call Me Free