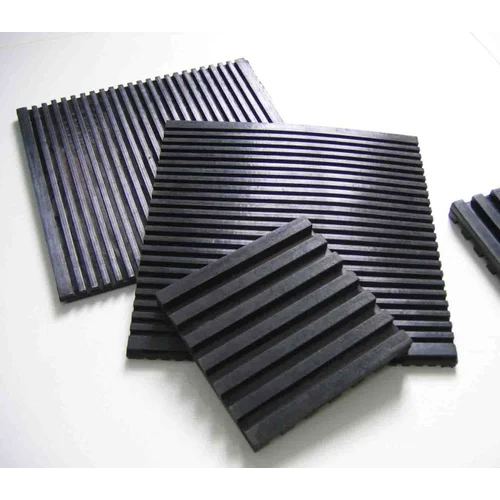

Sponge Rubber

10-5000 INR/Kilograms

Product Details:

- Size Standard and customized sizes available

- Temperature Resistance -40C to +120C

- Width 100 mm to 1200 mm

- Tolerance 0.5 mm

- Color Black

- Part Type Sheet, Roll

- Compression Ratio 20% - 30%

- Click to View more

X

Sponge Rubber Price And Quantity

- 10-5000 INR/Kilograms

Sponge Rubber Product Specifications

- 100 mm to 1200 mm

- 0.5 mm

- Standard and customized sizes available

- -40C to +120C

- 20% - 30%

- Sheet, Roll

- Sealing, cushioning, insulation, vibration dampening, soundproofing, gaskets, weatherstripping

- Black

- Smooth or textured as per requirement

- < 1.5%

- 2.0 MPa - 5.0 MPa

- <5% (by weight)

- Good resistance to water, mild acids, ozone, and aging

- EPDM, NBR, CR, NR, SBR (as per requirement)

- Plain, Adhesive-backed

- 30 - 45 Shore A

- 350 Gram per cubic centimeter(g/cm3)

- Continuous roll, sheets up to 10 meters

- Available in Natural or Synthetic Rubber

- Sponge Rubber Sheet

- 2 mm to 50 mm

- Sponge Rubber, Closed cell

- Lightweight, Flexible, Closed cell, Oil & weather resistant

- Variable (depends on size and thickness)

- Sponge polymer matrix

- Low

- Optional flame-retardant construction available

- < 5%

Sponge Rubber Trade Information

- 100 Per Week

- 1 Week

Product Description

Sponge Rubber provided by us, is widely used for variety of applications like cushioning, shock absorption, vibration dampening, weather stripping, and sound proofing. Because of its molecular structure, foam rubber is an excellent insulator.It's made up of small, closed-off gas pockets. Thermal insulation, filters, and bespoke gaskets all employ Sponge Rubber to meet various standards and approvals. As a result, air, water, and sound have a difficult time passing through it. This rubber is very effective as well as economical to use.

Superior Material Properties and Flexibility

Constructed from high-performance synthetic and natural rubbers such as EPDM, NBR, CR, NR, and SBR, our sponge rubber delivers excellent elongation, compression, and resilience. Its closed cell structure ensures low water absorption, outstanding insulation, and longevity in demanding industrial and commercial environments.

Comprehensive Customization and Versatile Applications

We provide a variety of color, size, and surface finish options, including plain or adhesive-backed forms. Manufactured in rolls or sheets (standard and custom sizes up to 10 meters in length), our products cater to sealing, cushioning, vibration control, and soundproofing, making them suitable for a diverse range of sectors.

FAQs of Sponge Rubber:

Q: How can I customize sponge rubber sheets or rolls to fit my specific project requirements?

A: You can request customization in terms of width (1001200 mm), thickness (250 mm), length (up to 10 meters), color, and surface finish. Both plain and adhesive-backed styles are available, and we offer rolls or sheets to match your application needs.Q: What are the typical usages and applications of this sponge rubber product?

A: These sponge rubber materials are frequently used for sealing, cushioning, insulation, vibration dampening, soundproofing, gaskets, and weatherstripping in automotive, construction, electronics, and general industrial applications.Q: When should I choose EPDM-based sponge rubber over other variants?

A: EPDM-based sponge rubber is especially suited to applications requiring excellent ozone, UV, and weather resistance. It offers superior performance outdoors or in environments with high exposure to sunlight and atmospheric conditions.Q: Where can I use this sponge rubber for electrical insulation?

A: Given its good electrical insulation properties, this sponge rubber can be used for insulation pads, barrier components, or protective layers in electrical enclosures and assemblies, provided the temperature range of -40C to +120C fits your application.Q: What is the process for ordering customized sponge rubber products?

A: Simply specify your requirements regarding dimensions, color, hardness, finish, and any special features (like adhesive backing). We accept orders in standard or custom specifications and provide packed items in polybags, cartons, or as per your instructions.Q: How does the closed-cell structure of this sponge rubber benefit my applications?

A: The closed-cell structure ensures minimal water absorption (less than 5% by weight) and superior resistance to environmental factors such as aging, ozone, mild acids, and oils. This results in long-lasting performance, especially for sealing and insulation purposes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Rubber Products' category

|

J. KHUSHALDAS & CO. (SPD)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send SMS

Send SMS Call Me Free

Call Me Free

Send SMS

Send SMS Call Me Free

Call Me Free